Michell-Baniki turbine

Practical Action

It can be seen from the characteristic performance curve of each turbine that the Michell-Banki

turbine continues to produce electrical energy during these times.

3. The selection of the diameter and spin speed of the turbine

To follow on from what was stated earlier, the diameter of this machine is not dependent on the

flow of water which allows a design with parameters that are independent of the flow of water.

This also means the turbine can continue to function within a wide range of different spin speeds.

As a result, the diameter of the turbine can be selected to begin with.

Many researchers indicate that diameters commonly used for small scale hydroelectricity are

between 200 and 500mm. The standardized diagrams which are offered in the bibliography are

frequently taken and used to select the diameter as the basis of the design.

Some of the factors that have to be taken into account are as follows:

In reducing the diameter of the rotor, one reduces the hydraulic performance

The biggest rotors have a lesser runaway speed

A certain proportion between the diameter and the width of the turbine needs to be

maintained in order to avoid excessively fast section changes between the ducts and the

nozzle, which would provoke strong reverberations in the moving fluid.

The parameters of the design need to be selected in order to allow simple manufacture of

the turbine

Once the diameter has been selected, the spin speed of the machine can then be determined:

n = 40.62.kc.√Hn

D

4. Number of blades on the rotor

The number of blades on the rotor is determined on the basis of the diameter and the working

conditions of the turbine, that is to say the height between the reservoir and the turbine and the

water flow.

One should keep in mind that a reduced number of blades can produce pulsations in the

generation of power, and more blades will produce an acceleration in the flow with the ensuing

rise of mechanical losses.

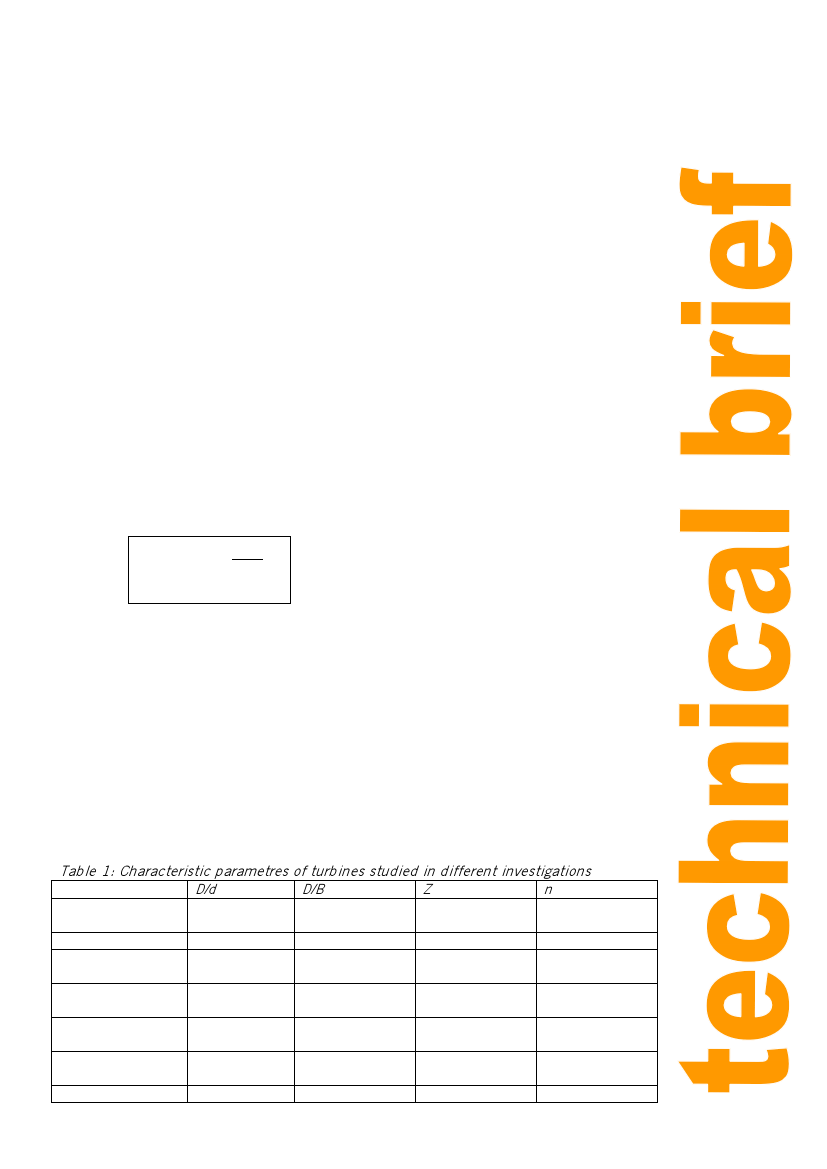

According to the research of A. Ulka and H. Olgun, there is an optimum number of blades. Table

1 shows the results of different research reflected in the literature documented.

Table 1: Characteristic parametres of turbines studied in different investigations

Reference

D/d

D/B

Z

n

Yokohama, 1985, 0.66

4.25

26

80.60

Japan

Vigm, 1986, CCCP 0.63

3.00

24

78.00

Ganz, 1984

0.66

1.00

30

75.00

Hungry

Alabama 1983

0.66

0.25

20

75.00

USA

Resita, 1983,

0.66

1.28

24

75.00

Rumania

KTU, 1987

0.54

0.81

24

71.30

Trazbon, Turkey

Oregon, 1949, USA 0.66

1.09

20

68.00

3